Central Supply

Odio et unde deleniti. Deserunt numquam exercitationem. Officiis quo odio sint voluptas consequatur ut a odio voluptatem. Sit dolorum debitis veritatis natus dolores. Quasi ratione sint. Sit quaerat ipsum dolorem.

The Elara 6

Quick and Compact

Compact and versatile, the Elara 6 is the ideal sterilization solution for any medical, dental or healthcare environment where speed and flexibility are required without compromising quality. The Elara 6 is a flexible and efficient tabletop autoclave designed to perform Class B sterilization for all types of instruments and materials: solid, hollow, porous, wrapped or unwrapped. An advanced computerized control system offers safety and ease of operation.

Outstanding Performance

- An efficient square chamber fits two wide trays which maximizes utilization of chamber space

- A built-in steam generator provides steam and facilitates the standby steam mode

- Automatic water filling option and continuous direct drain

- Frontal water filling economizes on space by eliminating the need to keep the top of the autoclave accessible

Safety Features

- A door locking device prevents a cycle from starting unless the door is properly locked

- Pressure safety valves prevent over pressurization in chamber and generator

- A safety thermostat prevents overheating in the chamber and generator

- Detailed and descriptive indicators and alarms greatly enhance convenience and safety

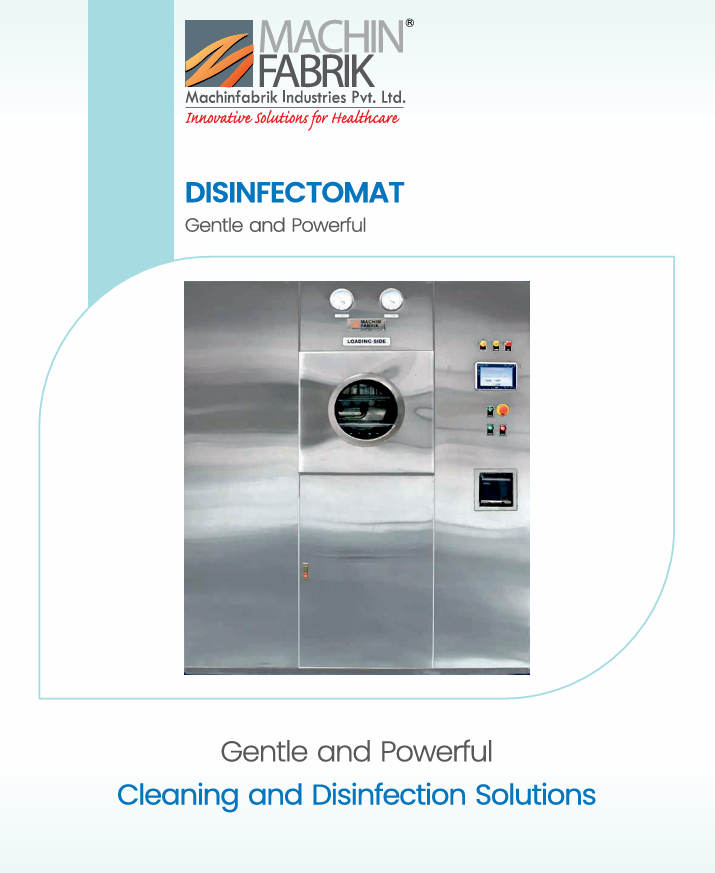

DISINFECTOMAT – Washer Disinfector

| MODEL | WD-S | WD-D |

|---|---|---|

| Application: Standard Washing/Rinsing/Disinfection (Drying Optional) | ✔ | ✔ |

| Chamber Size (600 x 600 x 800 mm) / Volume (288 Liters) | ✔ | ✔ |

| Overall Dimensions (mm) (W x H x D) | 1350 x 2000 x 1050 | 1350 x 2000 x 1050 |

| Chamber / Door / Piping / SS 304 (Optional Chamber SS 316 L) | ✔ | ✔ |

| Door / Large View Glass / Quick Locking Arrangement | Single Sliding Door | Double Sliding Door |

| High Capacity Circulating Pump / Automatic Dosing Pumps – 3 Nos | ✔ | ✔ |

| Loading Rack for Kidney Trays | ✔ | ✔ |

| Loading Rack for Glass Bottles | ✔ | ✔ |

| Loading Rack for Instruments | ✔ | ✔ |

| Loading Rack for Tubings (Optional) | ✔ | ✔ |

Utility Requirements

| Soft Water (3.0 Kg/Cm²) | 50 Liters / Phase | 50 Liters / Phase |

| Compressed Air (7.0 Bar) | 0.2 M3 / Min | 0.2 M3 / Min |

| Floor Drain 4” Dia | ✔ | ✔ |

| Electricity: 415V / 50Hz / 3 Phase / AC Supply | 6 KW & 2 HP | 6 KW & 2 HP |

| Drying Optional | 12 KW & 3 HP | 12 KW & 3 HP |

Standards

| CE Complaint | ✔ | ✔ | ✔ |

Automatic Operation

| Automatic Operation with PLC + HMI + Printer | ✔ | ✔ | ✔ |

STERIMAX : EO Gas Sterilizer

| MODEL | EMAX – 5 | EMAX – 8 | EMAX – 18 |

|---|---|---|---|

| Chamber Size (W x H x D) / Volume / Cubic Feet | 430 x 380 x 830 mm / 135 Ltr / 5 CuFt | 510 x 460 x 970 mm / 227 Ltr / 8 CuFt | 600 x 600 x 1200 mm / 430 Ltr / 18 CuFt |

| Overall Dimensions (mm) (W x H x D) | 900 x 1800 x 1000 | 1000 x 1900 x 1150 | 1150 x 2050 x 1390 |

| Chamber / Single Hinge Door / Piping / SS 304 | ✔ | ✔ | ✔ |

| Single Unit Dosing EO Cartridge | 100 gms | 170 gms | 300 gms |

| Cool Cycle: Gas Exposure / Temp / Humidity / Aeration | 270 mins / 38°C / 40–80% / 36 hrs | 270 mins / 38°C / 40–80% / 36 hrs | 270 mins / 38°C / 40–80% / 36 hrs |

| Warm Cycle: Gas Exposure / Temp / Humidity / Aeration | 60 mins / 55°C / 40–80% / 12 hrs | 60 mins / 55°C / 40–80% / 12 hrs | 60 mins / 55°C / 40–80% / 12 hrs |

| No Lumen Bore Restriction | ✔ | ✔ | ✔ |

| Entire Cycle Conducted Under Vacuum | ✔ | ✔ | ✔ |

Utility Requirement

| Distilled Water | 2 Liters | 2 Liters | 2 Liters |

| Compressed Air (7.0 Bar) | 2.2 Liters/Sec | 2.2 Liters/Sec | 2.2 Liters/Sec |

| Electricity: 415V / 50Hz / 3 Phase / AC Supply | 9 KW | 12 KW | 18 KW |

Safeties

| Process will not start unless the door is properly closed | ✔ | ✔ | ✔ |

| If chamber absolute pressure increases beyond set level, cycle will not start | ✔ | ✔ | ✔ |

| Emergency abort switch | ✔ | ✔ | ✔ |

Automatic Operation

| Automatic Operation with PLC + HMI + Printer | ✔ | ✔ | ✔ |

MEDISTER: Steam Sterilizer

| Specification | 600 x 600 x 900 | 600 x 600 x 1200 | 750 x 750 x 1000 | 750 x 750 x 1200 | 750 x 750 x 1500 |

|---|---|---|---|---|---|

| Chamber Volume (L) | 325 | 325 | 560 | 670 | 840 |

| Model | 325DMA-PLUS | 325DM-PL | 560DM-PL | 670DM-PLUS | 840DM-PLUS |

| Overall Dimensions (W x H x D) mm | 1450 x 2270 x 1850 | 1450 x 2270 x 1850 | 1800 x 2450 x 1850 | 1800 x 2450 x 1750 | 1800 x 2450 x 2050 |

| Chamber / Door / Piping / Steam Generator: SS 304 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Jacket: SS 304 | ✔ | ✔ | ✔ | ✔ | ✔ |

| Safety for Chamber / Jacket / Steam Generator / Door | ✔ | ✔ | ✔ | ✔ | ✔ |

| Working Temperature | 121°C / 134°C | ||||

Utility Requirements

| RO Water (3.0 Kg/cm²) | 20 L/cycle | 28 L/cycle | 43 L/cycle | 54 L/cycle | 54 L/cycle |

| Soft Water (2.0 Kg/cm²) | 105 L/cycle | 105 L/cycle | 105 L/cycle | 105 L/cycle | 105 L/cycle |

| Compressed Air (7.0 Bar) | 0.2 M³/min | 0.2 M³/min | 0.2 M³/min | 0.2 M³/min | 0.2 M³/min |

| Electricity (415V / 50Hz / 3 Phase / AC) | 18 KW & 25 HP | 24 KW & 35 HP | 30 KW & 35 HP | 30 KW & 35 HP | 30 KW & 35 HP |

| Floor Drain Ø | ✔ | ✔ | ✔ | ✔ | ✔ |

| Water Saving System with Chilled Water | Optional | Optional | Optional | Optional | Optional |

Standards & Norms

| ASME Section VII Div-1 | ✔ | ✔ | ✔ |

| IN-285 | ✔ | ✔ | ✔ |

| CE Compliant | ✔ | ✔ | ✔ |

Automatic Operation

| 600x600x900 | 600x600x1200 | 750x750x1000 | 750x750x1200 | 750x750x1500 | |

|---|---|---|---|---|---|

| Shelf / Carriage & Trolley | Shelf | 1 Carriage + 2 Trolley | 1 Carriage + 2 Trolley | 1 Carriage + 2 Trolley | 1 Carriage + 2 Trolley |

| PLC + HMI + Printer + Manual Backup | ✔ | ✔ | ✔ | ✔ | ✔ |

Ultrasonic Cleaner

The Ultrasonic Cleaner guarantees perfect cleaning of all delicate instruments used in hospitals.

- Single Tank : Contains only an ultrasonic tank.

- Two Tank : Includes an ultrasonic tank and a rinsing tank.

- Three Tank : Equipped with an ultrasonic tank, a rinsing tank, and a drying tank.

Cleaning & Disinfection

Wash Station

Wash Stations are provided with hot and cold water faucets along with compressed air connections for setting up the spray gun rinser. The fully stainless steel body ensures proper hygiene.

Multica Spray Gun

The “Multica” Spray Gun is the most valuable instrument for hospitals, laboratories, and all establishments where effective cleaning is essential.

It makes it possible to clean instruments and rubber tubing quickly and thoroughly using water and compressed air.

Drying Cabinet

MachinFabrik’s fully automatic, accurate, and reliable drying cabinet is suitable for drying and sterilizing equipment in medical and research laboratories.

The accuracy of the process is ensured by a precision thermostat, which ensures accurate and uniform temperature.

- Electronic timer to accurately control the drying period.

- Thermostat cut-off against overheating.